Introducing… Project 5. The second of four Physical Demonstrator Projects here at TIES Living Lab. The project is managed by Transport for London (TfL) and supplied by Mavin.

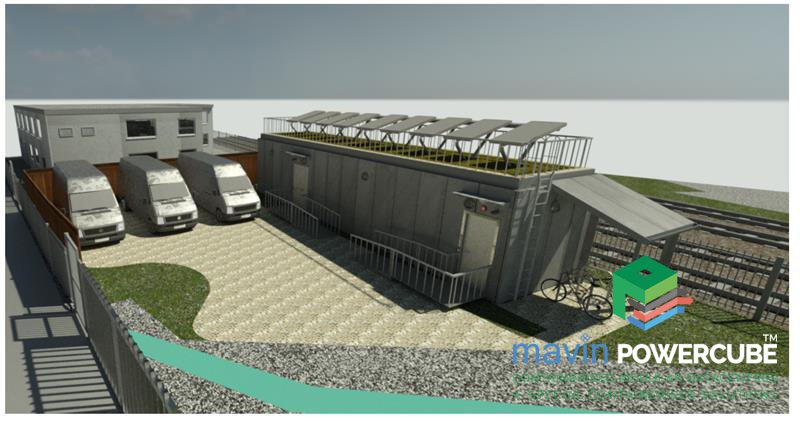

This is the first of its kind, custom modular Signalling Equipment Room (SER). The client, TfL, want to evolve their SER environments quickly and efficiently, utilising Modern Methods of Construction (MMC). As an example of this the Powercube is a British, custom designed and built, containerised, re-deployable, flexi-environment.

The uniformity of a generic standard containerised SER design is absolutely vital for achieving large scale, cost, operational and environmental efficiencies driving down the hard material costs, streamlining the manufacturing process, and enabling known cost options for deployment and on-going operational costs.

With the required rapid replacement and much needed evolvement of the UK rail networks aged signalling environments, the number of these required could run into the thousands and with savings of 40% to 50% for each Powercube, millions of pounds can be saved from the public purse.

Combine this with associated additional cost savings in respect to the on-going operation of a more efficient environment, reduced maintenance and upkeep, increased use of renewable energy per SER and significantly less on-site civils disruption when deploying, as well as line-side health and safety and the re-deploy ability, the Powercube is a fantastic example of collaboration between Government and the private sector.

Project Objectives:

- Create a new generic standard for equipment rooms reducing future infrastructure time, cost and risk

- Develop a modular and adaptable communication room that will be used as a test mule for the purpose of introducing new technology

- The new technologies include but are not limited to free-flowing cooling units and PV cells for domestic services

- Demonstrate the ability to expand the volume of the structure without affecting the operational equipment housed inside

Project Outcomes:

- Demonstrate the potential for improved efficiency (both in the design and construction phases) by using modular and off-site construction over traditional building methods

- Demonstrate the potential to reduce future costs of designing and installing new equipment rooms by using modular and off-site construction

- Demonstrate the potential to reduce health and safety risks on future equipment room builds by using modular and off-site construction

- Demonstrate the potential to reduce all sort of disruptions usually created by traditional construction works (e.g. noise levels) by using modular and off-site construction

- Demonstrate the potential to reduce environmental impact, if modular and off-site construction is used on future equipment room projects